Why You Need DTF Printing Supplies?

The reason you need DTF supplies is because only these types of supplies can be used. Other printing supplies will not help you use the DTF printer properly and smoothly.

This also means that DTF printers are not allowed to use other printing supplies. The right supplies are essential to ensure smooth operation and high quality printing.

These consumables include ink, transfer film, adhesive powder (DTF powder), and more. Each of these components plays an important role in the printing process, comprehensively affecting clarity before printing and durability after printing!

Since consumables are so important for DTF printers, you need to take extra care when choosing it. Often, the wrong choice can cause all sorts of problems with printing.

For example: DTF hot melt powder “sticky powder” phenomenon, DTF Ink color is not correct (visual “color cast”).

Points to focus on when choosing DTF supplies

I believe you don’t want your DTF printing to have similar problems, so here we suggest you to focus on the following issues when choosing consumables.

- Brand Reliability: Supplies on the market are by and large similar. DTF supplies from big brands may not always be good. When faced with a wide variety of brands, the first thing you should focus on is the level of reliability it offers. Reliability can be defined in terms of after-sales answers, quality assurance, and stable supply. When you think that a certain brand has two out of the above three points, then you can consider working with them in the long run.

- Cost controllability: There are many DTF consumables that are consistent in printing results, but their prices vary widely. Identifying a particular brand of consumables at the outset may cause you to miss out on other, better options. To avoid this type of situation, you can try to buy more consumables for testing. Compare and contrast the difference between each brand of consumables. Achieve cost control while meeting your printing requirements.

What Exactly Is Included In DTF Printing Supplies?

You may think that DTF supplies are only inks, films and powders, but in reality these three things alone are not enough at all. You also need to realize that there is some expanded knowledge about them.

DTF pigment ink

When there is a printer, there is an ink, and DTF ink is a water-based ink, which is different from the traditional oil-based ink. It is also known as “pigment, paint” ink. Usually these inks are available in a variety of colors, the most common being 5 (C/M/Y/K/W), and the advanced ones are available in 9 colors (C/M/Y/K/W + FM/FY/FO/FG). Among all colors of DTF ink, white ink is the most consumed.

It is important to note that colored inks do not mix. Often inks with more colors will contain all of them, and it’s best to buy the same ink model at the time of purchase. If you mix different models or brands of ink, it may result in a color difference in the ink.

The reason for this phenomenon is that inks are not formulated the same way as each other, and the strength of their chemical properties can lead to differences in color reactions.

- Example: Printing with two brands of ink at the same time, one ink contains the colors C/M/Y/K/W, while the other ink contains the colors FM/FY/FO/FG.

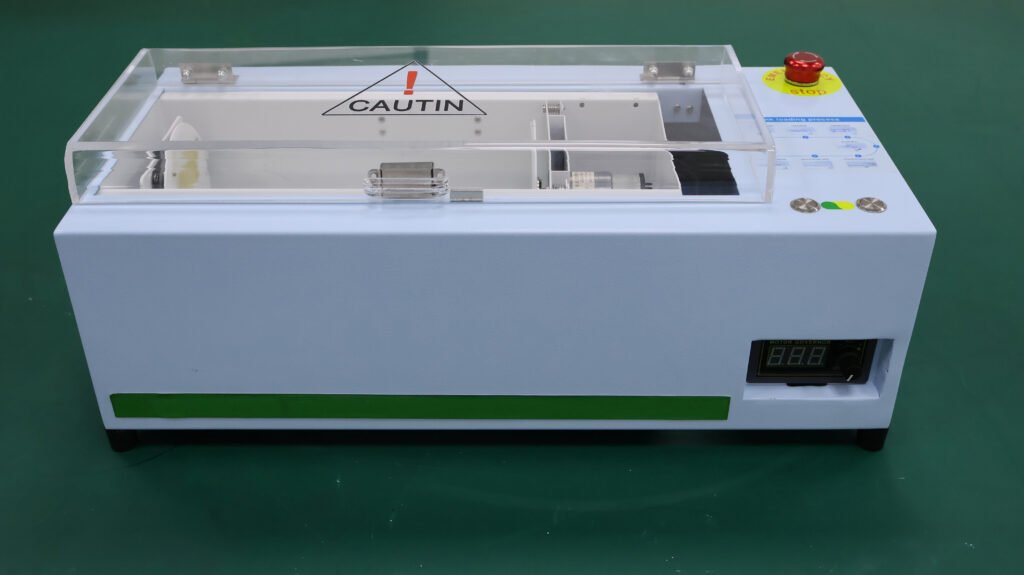

Ink usually needs to be “shaken” before use to prevent the pigment particles in the ink from settling. For this reason, there is a equipment called a “white ink shaker” on the market. Since white ink is a frequently used ink, it needs to be shaken frequently.

DTF transfer film

The transfer film is essential for the printing of graphics onto the substrate. This transparent plastic film is also known as PET film. the full name of DTF is “direct-to-film“, so you can imagine the importance of the film in this context.

There are different types of films. The majority of films are designed to provide a special effect on the surface of the substrate after the pattern is transferred. Like frosted film, glow-in-the-dark film, color film, color change film and so on. If you want to know more about films, please refer to: click here.

Film alone is not enough, you need a heat press to make the transfer. After the film has been processed in other, transferring with a heat press will be the last step.

The transfer of a film to a substrate by means of a heat press requires the use of high temperatures. This step is often referred to as “heat press transfer“. If the temperature is not set correctly, a complete set of consumables can be wasted.

DTF hot melt powder

DTF hot melt powders are usually used after the ink has been printed onto the film. The main purpose of the powder is to provide durability and some special features to the ink. Powders also provide adhesion and are an integral part of the transfer.

There are also different types of powders. For example, anti-static powder, soft powder, white or black powder, and so on. All of them can give some special effects to the pattern after transfer. For example, anti-static and soft touch.

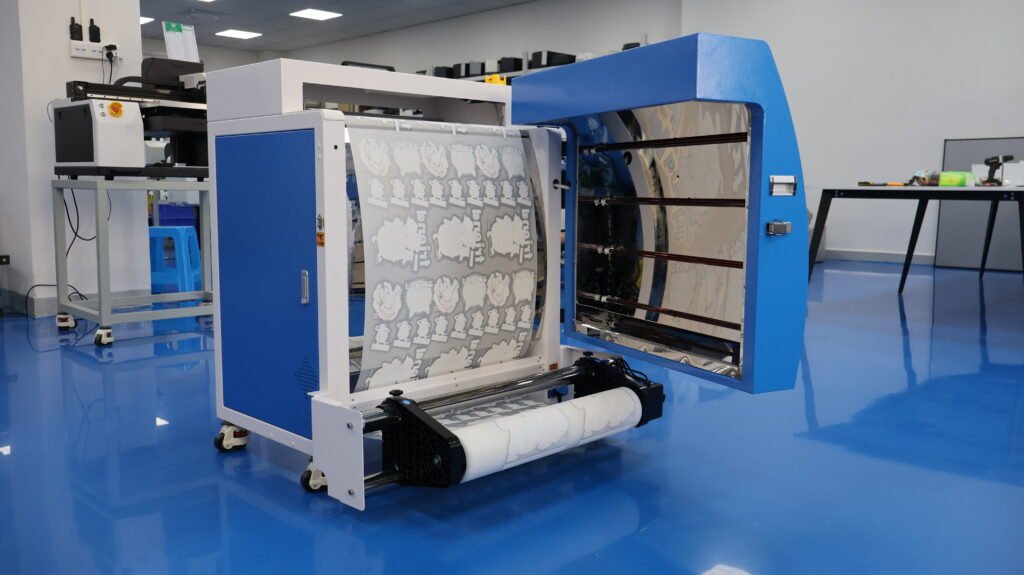

The powder is not “sprinkled” on the film and then it is ready for use. The powdered film actually needs to be “baked”, which requires the use of a DTF oven. The function of the oven is to “melt” the powder on the film by baking.

With the continuous development of the market, there is now a powder shaker in addition to the DTF oven. This is a device used to “shake” the powder. Manually “dusting” the film can be tricky, especially when it comes to filtering out the excess powder.

The film cannot be covered with hot-melt powder, but only in the area covered by the ink. If hot melt powder is also present outside the inked area, yellowing may result.

There are many printing problems caused by powder, and there are many devices related to powder. During printing, poor adhesion of the transfer may occur. After printing, the transfer pattern may not be durable (easy to crack, not resistant to washing).

Conclusion

Ink, film, and powder are the three consumables that must be used for DTF printing. And the related equipment that come from these consumables are equally important. You can’t just rely on the printer to complete the printing, every part is important. Below is a summary of the consumables or equipment you will use for DTF printing.

- Consumables: DTF ink, DTF PET film, DTF hot melt powder.

- Related equipment: DTF printer, DTF oven, DTF powder shaker, Heat press, White ink shaker.

It’s important to note that, aside from the DTF oven and heat press, the other equipment is not essential. Similar results can be achieved manually. You don’t need to buy everything if your printing efficiency isn’t affected.

Tips For DTF Printing Supplies Shopping

The most important thing about purchasing DTF consumables is to follow the principle of “test before you buy“. In the current printing market, the manufacturers of consumables usually give you the corresponding test reports and invite you to go to the site to personally observe the test results. But in addition to this basic principle, there are some suggestions below that can help you.

Buy in bulk for discounts

Purchasing DTF printing supplies in bulk often comes with significant savings. Look for suppliers offering bulk discounts, and calculate your usage in advance to avoid running out of supplies unexpectedly.

Comparison shop for the best prices

Don’t settle for the first deal you find. Compare prices from different suppliers, ensuring you find the best combination of quality and affordability. Always prioritize reputable sellers known for quality products.

If you’re purchasing in large quantities, don’t hesitate to negotiate for better pricing. Many suppliers are open to offering customized deals for large-scale buyers.

Take advantage of supplier deals

Many suppliers offer promotions, discounts, or loyalty programs for repeat customers. Keep an eye out for these offers to get more value for your money.

Focus on quality, Not just price

While it may be tempting to go for the cheapest DTF supplies, remember that investing in quality materials will save you money over time. A balance between price and performance is key to long-term success.

Assess the total cost of ownership

When evaluating DTF supplies, consider the long-term costs, including maintenance and replacement parts. Cheaper materials may lead to increased costs in the future due to poor performance or higher maintenance needs.

Optimize DTF supplies usage

To minimize waste, fine-tune your printer settings and ensure efficient ink usage. Regular maintenance and optimizing print designs can reduce ink consumption, saving you money in the long run.