Why is the quality of DTF transfer film so important?

The reason is simple: it directly affects the final transfer result. DTF printing doesn’t print ink directly onto the substrate. Instead, it prints the ink onto a film, applies powder, and then heat-presses the film onto the substrate.

Why does this affect the results after the transfer? This is mainly because the DTF transfer film has a coating on it. The coating is like a layer of dyed cloth that is used to color the ink on top. The coverage and penetration of the “dye cloth” is directly related to the clarity of the print pattern.

The purpose of adding powder is to allow the ink to adhere and cure on the film and to ensure that the edges of the inks are clean and free of spills. Since heat pressing is done at high temperatures, the film also needs to be able to withstand high temperatures and should not be deformed or blistered.

Here are some simple ways to identify quality. Hold the film up to the light and check for evenness in the coating texture. After transfer, observe whether it peels easily and whether all the ink transfers to the substrate. Film that meets these criteria is usually of good quality. However, keep in mind that sometimes problems during other printing stages may be mistaken for poor film quality.

Characteristics of different types of DTF transfer film

DTF printing films have basic property differences such as single-sided and double-sided, matte and glossy, hot peel and cold peel. There are also special films that bring a different experience to printing.

One thing that needs to be clarified here is that basic properties can appear on special films.

Common specialty films found in the market include:

- Frosted(matte) film: give the pattern a frosted finish.

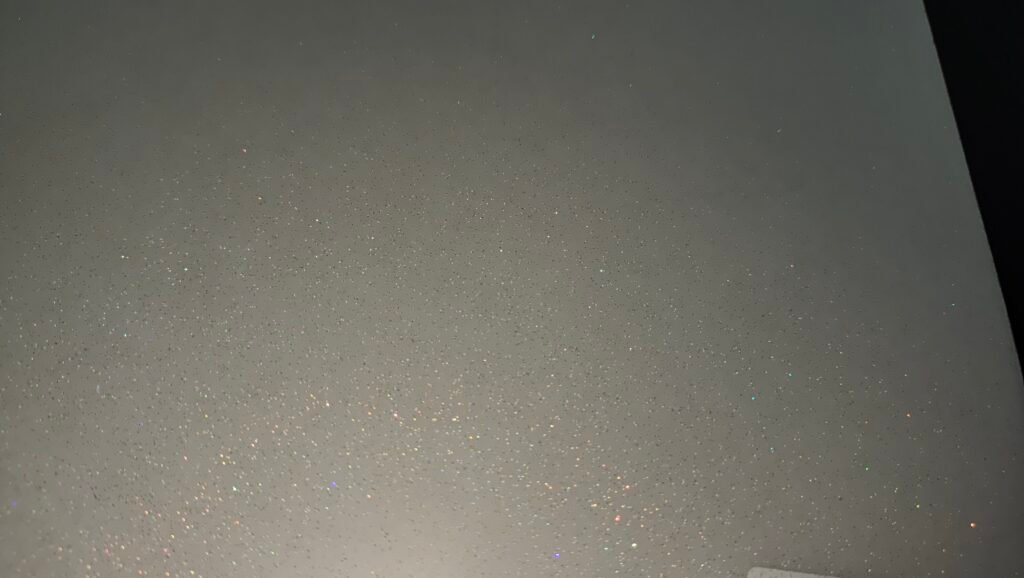

- Glitter film: give the pattern a shimmered effect.

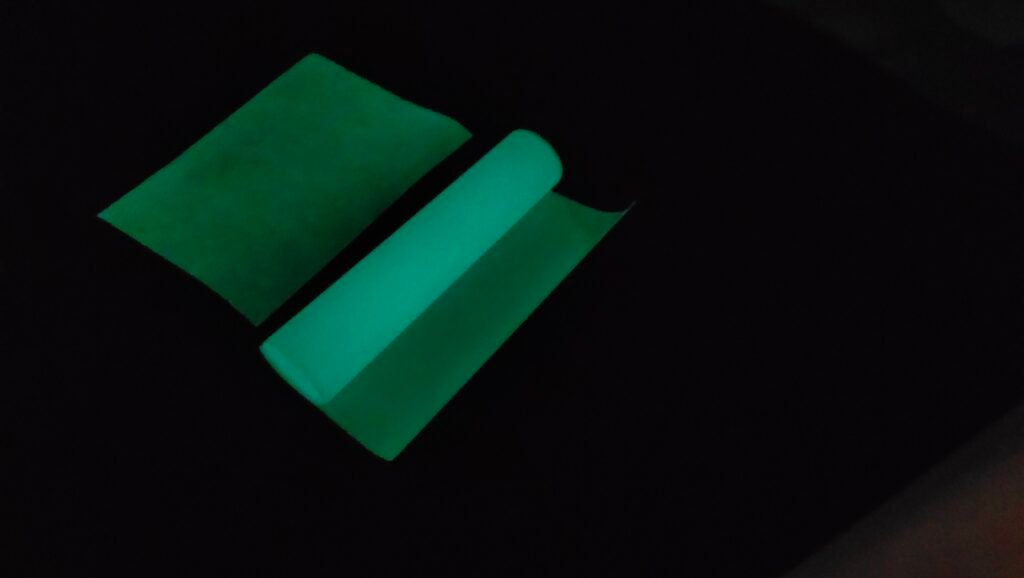

- Fluorescent film: give the pattern a boasts richer colors.

- Golden film: give the pattern a glittering gold effect.

- Silver film: give the pattern a shimmering silver effect.

- Breathable film: enhance the breathability of the fabric’s printed design.

- Instant peel film: tear immediately, no cooling time needed.

- Colorful film: enhance the pattern’s brilliance using reflective properties.

- Thermochromic film: enable the pattern to change color based on temperature fluctuations.

As you can see, different films can give different effects to the transfer pattern. In most cases, these special films require you to contact the supplier for customization. Considering that it is not a product with a high percentage of demand in the market, it is rarely sold directly.

The most common requirements in the current market are:

- Matte single-sided films are suitable for most printing jobs, ensuring stable ink absorption and transfer quality.

- Matte double-sided film are more ink-absorbent than single-side masks and are commonly used for more intricate pattern designs.

- The custom-designed printed appearance requires special thin films.

Secondly, hot peeling and cold peeling have different prices. They are used to cope with different production needs. Hot peel transfer printing is faster and has more advantages in bulk printing. Cold peel transfer printing, on the other hand, produces more durable prints and is better suited for high-quality printing.

Furthermore, the thickness of films varies, with both thick and thin films having their own applications and being useful in different printing designs.

How do you choose from the myriad of DTF transfer film available?

Based on the above information, picking the right DTF transfer film is not difficult. The key is that you first need to be clear about what substrate these films will be used on and how they will look when printed on.

The key to your film selection is whether or not it will give you the full effect on the final substrate. There may be another type of film that is more suitable for this type of substrate.

Whether you choose hot or cold peeling depends on how much you value the durability of the final print. The same goes for needing the print to be glossy or non-glossy.

Find a film that matches the content you want to print. Check how the coating looks, how the DTF printing film absorbs the ink, and the printing speed.

The thickness will affect the lifespan of the film and the printing effect. Experiment with different types of films to find the best fit for your budget.

4 tips for using DTF printing film

DTF printing process is simple and complex, the key lies in the details of control. There are times when knowing how to operate can also play a more effective.

- Let the film cool as much as possible for a minute or so after printing, whether your DTF transfer film is hot or cold peel.

- Whether to use hot or cold stripping depends on the particle size of the hot melt powder. Larger particles generally lend themselves to cold stripping, while smaller particles are better suited to hot stripping.

- After transfer using the special film, consider pressing again (but not re-hot pressing). This ensures the printed design retains the special effects imparted by the film.

- Proper storage is crucial when the film is not in use. Click here for storage instructions.

Frequently Asked Questions

What temperature is required for film transfer?

Typically requires between 145-165 degrees Celsius while pressing for 6-15 seconds (depending on substrate type and film thickness).

Does film have an expiration date?

Yes, in general, film has a shelf life of about two years. It has a shelf life because, over time, the effectiveness of the film coating diminishes and becomes a regular film.